🚀 Successful Delivery: 108L Low-Temperature Hydrogen Peroxide Plasma Sterilizer to Kyrgyzstan

1. Background: Enhancing Infection Control with Advanced Sterilization Technology

In modern healthcare, infection prevention and control are critical to ensuring patient safety. A leading hospital in Kyrgyzstan was facing sterilization challenges due to an increasing number of delicate medical instruments requiring low-temperature sterilization. Their existing sterilization equipment struggled with long processing times, residual chemical risks, and high maintenance costs.

To meet international medical sterilization standards and enhance operational efficiency, the hospital sought an advanced sterilization system that is fast, safe, and highly effective for medical-grade disinfection. They turned to SADA Medical, a trusted global supplier of cutting-edge sterilization equipment, for a tailored solution.

2. Understanding the Customer’s Needs

🔍 Key Challenges and Pain Points Faced by the Hospital:

🔥 1. Safe Sterilization for Heat-Sensitive Medical Instruments

Many critical medical instruments, such as endoscopes, fiber optic devices, and surgical tools, cannot withstand high temperatures used in traditional steam autoclaves. The hospital needed a low-temperature sterilizer to prevent instrument warping, degradation, or functional impairment.

💡 SADA Medical’s Solution:

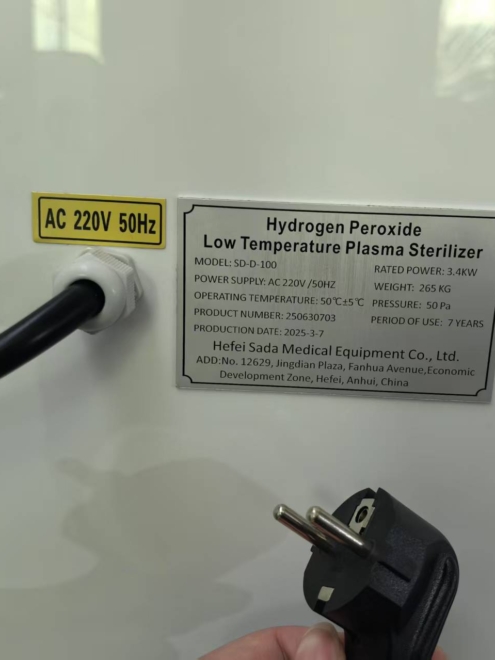

The SD-D-100 Low-Temperature Hydrogen Peroxide Plasma Sterilizer operates at 50°C ±5°C, ensuring 100% sterilization efficiency without causing any damage to heat-sensitive instruments.

⏳ 2. Faster Sterilization for High Patient Turnover

Delays in sterilization can disrupt surgical schedules and reduce patient care efficiency. The hospital’s existing sterilization process was too slow, limiting the availability of sterilized instruments.

💡 SADA Medical’s Solution:

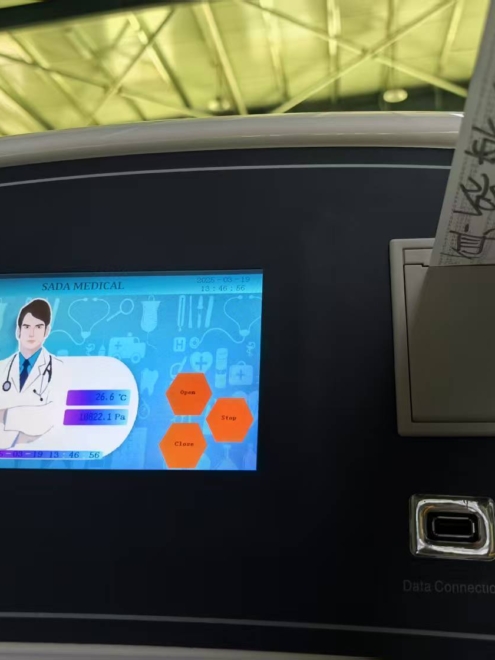

- Quick Mode (40 minutes): Ideal for emergency sterilization needs.

- Enhanced Mode (60 minutes): Provides deep sterilization for highly contaminated tools.

- One-touch, fully automatic operation: Minimizes human error and optimizes workflow efficiency.

🛡 3. Ensuring Operator and Environmental Safety

The hospital required a sterilization system with minimal chemical residue, low emissions, and maximum safety for medical staff and patients. Traditional sterilization methods posed risks due to residual toxic gas and high pressure requirements.

💡 SADA Medical’s Solution:

- 99.5% efficient residual gas filtration system, removing particles ≥0.3μm, ensuring no harmful residue remains.

- Overpressure and overtemperature protection, with built-in high-temperature and low-pressure alarms for maximum safety.

- Medical-grade HEPA filtration system that eliminates potential contamination risks.

📜 4. Compliance with International Medical Sterilization Standards

To maintain a sterile environment and comply with GMP (Good Manufacturing Practice) and Class II medical device certification, the hospital needed a reliable and internationally compliant sterilization system.

💡 SADA Medical’s Solution:

The SD-D-100 meets all global sterilization requirements, making it ideal for hospitals, laboratories, and pharmaceutical applications.

3. SADA Medical’s Tailored Solution: SD-D-100 Low-Temperature Plasma Sterilizer

✅ Product Delivered: 1 unit of SD-D-100 Low-Temperature Hydrogen Peroxide Plasma Sterilizer

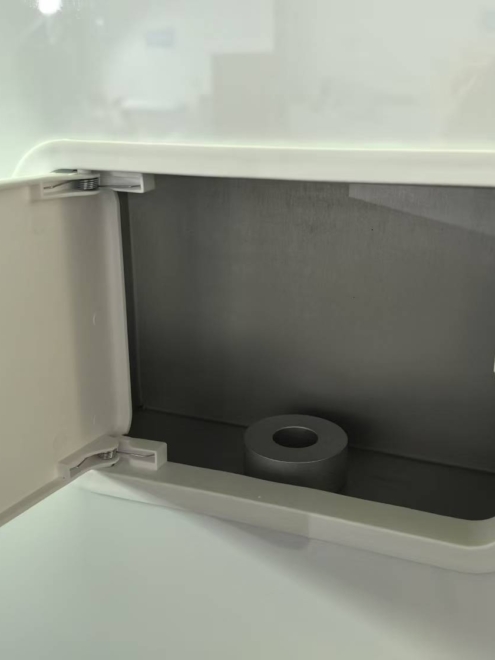

✅ Sterilization Capacity: 108L chamber, handling multiple instruments per cycle

✅ Sterilization Technology: Hydrogen peroxide plasma sterilization at 50°C ±5°C for delicate medical instruments

✅ Automation: Fully automatic sterilization process, reducing manual labor and error risk

✅ User-Friendly Features: 7” LCD touchscreen display, built-in mini printer for record-keeping

✅ Safety Measures: Overpressure protection, real-time alarms, and medical-grade HEPA filtration

4. The Results: A Faster, Safer, and More Efficient Sterilization Process

💬 Customer Feedback from the Kyrgyzstan Hospital:

“Before using the SD-D-100, we struggled with sterilizing our delicate instruments safely. Traditional autoclaves were too hot, and chemical sterilization was time-consuming. Now, with this low-temperature plasma sterilizer, we can process our tools much faster without damaging them. It has completely transformed our sterilization workflow!” – Hospital Sterilization Manager

🔹 Sterilization Speed Increased by 50% – The hospital can now sterilize more instruments per day, reducing procedure delays and improving patient care.

🔹 Zero Damage to Delicate Instruments – Endoscopes, fiber optic tools, and surgical instruments remain intact and fully functional after sterilization.

🔹 100% Compliance with International Standards – The SD-D-100 meets GMP, Class II medical device, and international sterilization safety regulations.

🔹 Enhanced Staff Efficiency – The fully automated sterilization process reduces manual work, allowing hospital staff to focus on patient care.

🔹 Eco-Friendly and Safe – The hydrogen peroxide plasma process leaves no harmful residues, making it safer for both patients and medical staff.

5. Looking for a Reliable Sterilization Solution? Contact SADA Medical Today!

Is your hospital, medical center, laboratory, or pharmaceutical facility in need of a fast, efficient, and medical-grade sterilization solution?

🔹 Protect delicate instruments with low-temperature plasma sterilization

🔹 Enhance sterilization speed and efficiency with automated processes

🔹 Ensure 100% safety with advanced filtration and alarm systems

🔹 Stay compliant with global sterilization standards

📩 Contact SADA Medical today by Below Contract Form and upgrade your sterilization capabilities with the latest in hydrogen peroxide plasma technology! 🚀