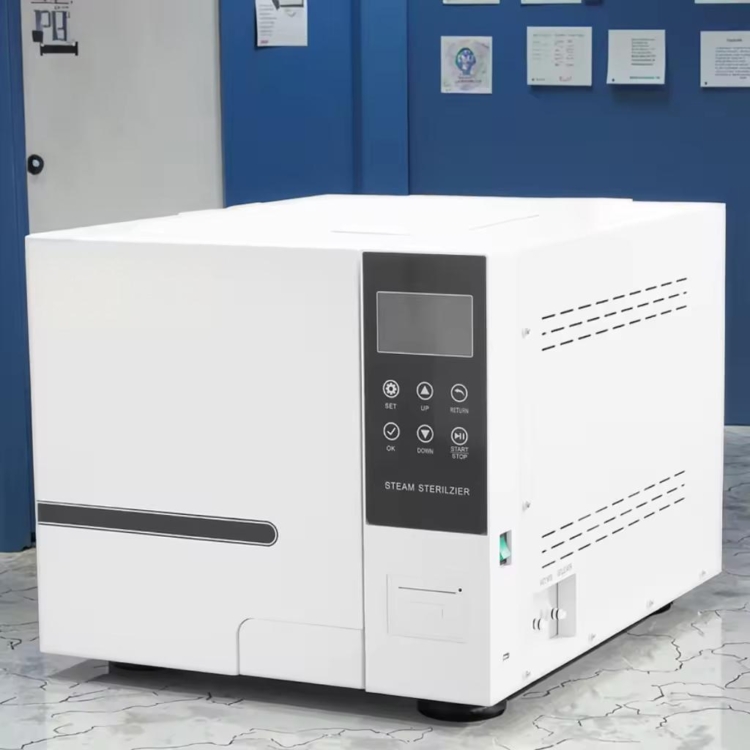

Sada 200L Large Vacuum Steam Autoclave PLC Control Sterilizer

Sada Medical HA-BA Steam Sterilization Medical Devices Horizontal Rectangular Autoclave with Printer

200L Large Vacuum Steam Autoclave PLC Control

Model: SD-VSA

Sterilizing Volume: 200L

Application:

Medical Instrument Sterilization Autoclave are widely used in microbiology, medicine, podiatry, tattooing, body piercing, veterinary science, mycology, funeral homes, dentistry, and prosthetics fabrication.

They vary in size and function depending on the media to be sterilized. Typical loads include laboratory glassware, other equipment and waste, surgical instruments and medical waste.

Sterilization Objects: Unwrapped or Wrapped instruments, Sugircal instruments, Glassware, Liquid , Culture Media, Rubber Material, Gowns, Dressing, Gloves, etc.

Shipping Port:Shanghai, Qingdao, Ningbo, Shenzhen, Guangzhou, etc.

Lead Time:20 – 25 working days.

Features of Horizontal Pressure Steam Sterilizer

1. 3-times pre-vacuum, effective discharge cold air from chamber to improve steam efficiency.

2. Internal steam generator, PLC control, space and energy saving.

3. The post-sterilization hot steam is cooled down before discharge from machine.

4. Equipped with water quality monitor, extend the machine service life.

Specifications

Brand: Sada Medical

Model: SD-VSA

Sterilizing Volume: 200L

| Capacity | 200liter |

| Power supply | AC380V, 50HZ |

| Working Pressure | 0.21-0.23MPa |

| Safety Over-pressure | 1. Over-pressure warning alarm 2. Safe pressure relief valve 3. Over-temperature shut-off device |

| Safety Door Interlock | PLC Set: the door can’t open while vessel is under pressure; can’t start up if the door is not properly closed. |

| Safety Emergency Shut-off | In a readily accessible location |

| Safety Surfaces | Surfaces NOT exceeding 50°C |

| Door | Mechanical rotating locking with electronic sensor |

| Indicator For Temperature | ±1% accuracy over the scale range 50°C to 150°C; 0.1°C resolution for digital display |

| Display Indicators | Door locked, operation in progress, major operating cycle stages, and cycle complete, times, temperature, pressure, fault condition readable by normal vision from a distance of 1.2m |

| Manuals | English language 1. Operation instructions (including process description) 2. Loading and maintenance procedures 3. Short-form of operation and loading procedures |

| Spare parts (option) | 1. Heating element 2. Door seal/ gasket 3. Replacement air filter 4. Safety valve 5. Pressure and temperature gauges |